Downstream processing

Following the production of bio-based chemicals by chemo-catalytic or biotechnical conversion the products need to be isolated and purified. Without such downstream processing steps no production process can be carried out.

Bio-based chemicals produced by chemo-catalytically or biotechnologically processes are normally dissolved in a reaction medium when the reaction has been completed and product isolation and purification are necessary to obtain high-purity products. Therefore suitable and inexpensive downstream processes need to be developed and adapted for every reaction based on unit operations such as filtration, distillation, extraction, crystallization, adsorption, membrane processes and chromatography.

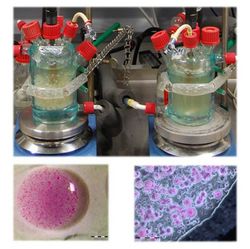

In some cases the conversion process and product isolation may be beneficially combined leading to a more efficient conversion. For instance, we could obtain a higher product amount in the biotechnological production of n-butanol by applying in-situ extraction of the toxic product n-butanol.

Furthermore, an in-situ product removal may be beneficially applied in the acid catalyzed production of 5-hydroxymethylfurfural (HMF). In our research we used an in-situ-adsorption of HMF on activated charcoal to protect HMF from decomposition and to increase the HMF yield.

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)