Biotechnical conversion

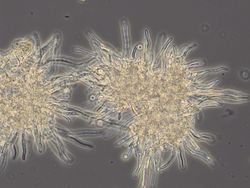

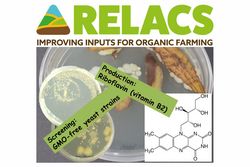

Biotechnological processes are essential for a sustainable bio-economy in the future. The diverse biocatalysts (like enzymes, bacteria, fungi and algae) are characterized by a high selectivity and mild reaction conditions. This predestines them for an environmental sound conversion of renewable resources to higher value products.

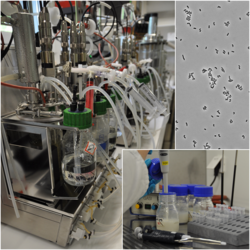

Due to the high selectivity of biotechnological reactions and the mild reaction conditions (pressure, temperature and pH-values), the costs of a biotechnological process compared to an established petrochemical processes can be reduced. The development and optimization of bioprocesses comprises screening and selection of feedstock, biocatalysts, products as well as optimizing the reaction conditions.

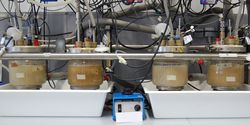

The main targets of an industrial feasible process are beside high product concentrations and productivities, the product yield in terms of the supplied substrate. To get fast results under efficient experimental conditions, we use high throughput processes in µL-scale. We are screening own production strains using these processes. Further process optimization is done in bioreactor systems, where the influence of e.g. pH and oxygen are investigated. These cultivations can include the use of online analytics.

The main fermentation substrates used in cultivations are pure sugars and glycerol, but alternative resources like hydrolyzates from residual materials gain more importance. The use of these materials brings new challenges for the cultivation of microorganisms. They often contain inhibitors or other impurities, which interfere with the growth or product formation. The hydrolysis of residual materials is examined in our institute by the working group biomass digestion. The cooperation of the two fields helps us to optimize the hydrolysis in regard to a later use as substrate for cultivations.

Our institute has over 20 years of experience in the field of bioconversion from renewable resources and the development of immobilization processes. This work includes the following products:

- Itaconic acid

- D-lactic acid

- Succinic acid

- 1,3-propanediol

- 2,3-butanediol

- n-butanol

- 3-hydroxypropionaldehyde

- Isomaltulose (Palatinose)

- L- methionine

- Lipids from algae

In many of these fields we were able to achieve significant improvements, like the screening and production of new or more suitable biocatalysts, the application of immobilized biocatalysts and by systematic improvements of the fermentation processes.

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)