Project

Novel shrimp peeling machine to improve the North Sea shrimp value chain

North Sea or brown shrimps (Crangon crangon) are caught and consumed in Germany. However, they have already travelled a long way before they end up on our plates. Most brown shrimps are de-shelled (“peeled”) by hand in Morocco and then brought back to Germany as a processed sea food. The increase in value therefore takes place in other regions.

Funded by the state of Lower Saxony, scientists at the Thünen Institute of Sea Fisheries, together with the Georg August University of Göttingen and the company US Processing Klever UG, are investigating whether and how brown shrimps could be mechanically de-shelled in the fishing region to rebuild a regional value chain.

Background and Objective

Very few seafood products are consumed fresh at the place where they are caught. Instead, they undergo a series of processing and transport steps between catch and consumption, which gradually increases the value of the product. As each step requires special skills and should be as cost-effective as possible, such value chains are usually very efficient, consist of various intermediate players and are often organised across national borders. The downside of efficiency is often a high susceptibility to disruptions in the chain's processes. The effects of these disruptions particularly often affect the fishermen, as they have rarely any alternative options, unlike processing companies or consumers.

The brown shrimp fishery in Germany is also less resilient to external shocks, as the COVID-19 pandemic has shown. For reasons of efficiency, the shrimps caught in the southern North Sea are mainly transported via the Netherlands to Morocco, where they are peeled by hand in large de-shelling centres and then returned to Europe for resale after being preserved several times. When de-shelling capacities in Morocco were greatly reduced to contain the pandemic through social distancing rules and limits on the number of people per space, the volume of shrimps taken by wholesalers fell, and so did the catches themselves and thus the earnings of shrimp fishing companies in Germany. These losses could not be compensated for due to a lack regional de-shelling operations and a lack of alternative marketing channels.

Our research and development project aims to identify solutions for a regional value chain and to evaluate them in terms of their social and economic sustainability according to scientific criteria and standards. The basis for this is a new type of machine with which shrimps can be de-shelled without contact. As part of the project, we are developing, building and testing the prototype of a de-shelling unit. Its functional principle is based on using pressure waves to break open the shrimp carapace, which then separates from the meat. In addition to the technical feasibility, we are also researching the economic side of this shrimp peeling 3.0 (after the old manual peeling and after already existing machines which however work with contact). We are also investigating whether there is a market for the regionally de-shelled brown shrimps and whether the resulting remains can be utilised regionally. Our aim is to develop economically and socially viable solutions for the struggling brown shrimp fishery.

Approach

The R&D project has five interlocking and complementary focal points:

- Project coordination and public relations: Drs Ralf Döring and Arne Schröder from the Thünen Institute of Sea Fisheries coordinate and manage the project. They are responsible for knowledge transfer, informing the fishery and the public and publishing interim and final results. Additional tasks include the organisation of project meetings and cooperation with the project advisory board.

- Construction and testing of a new type of shrimp peeling machine: In this focus area, the company US Processing Klever, together with the German Institute of Food Technology, is building and testing the new type of shrimp peeling machine. We use the data from test runs of the unit to analyse the economic efficiency of the new shrimp de-shelling technology.

- Efficiency analysis of shrimp fishing: Dr Tim Knöpfel from the Department of Agricultural Market Economics (Prof. Bernhard Brümmer) at the University of Göttingen is investigating the economic efficiency of the German shrimp fishery, also under the to be determined conditions of the future regional operation of the new shrimp de-shelling technology.

- Economic analyses and innovation diffusion shrimp peeling machine: Dr Tobias Lasner and Melina Niemann from the Thünen Institute of Sea Fisheries are investigating the effects of the new type of shrimp peeling machine on the profitability of German fishing companies. They are incorporating the results of the market analysis (see 5.) and the technical trials (see 2.) in order to make empirically based assumptions about the economic potential and risks of an alternative way of adding value to North Sea crabs.

- Market analysis for regionally de-shelled shrimp: A team led by Prof Antje Risius and Dr Brianne Altmann from the Department of Marketing for Food and Agricultural Products at the University of Göttingen is researching the changes in market potential and consumer attitudes towards brown shrimps that could be made possible by the establishment of a regional de-shelling industry.

The Thünen Institute has also awarded two subcontracts. The ttz Bremerhaven is investigating the regional utilisation possibilities of shrimp peeling remains and the quality of the shrimp meat. Sector experts Nicole Knapstein and Thomas Collande provide us with information on the current brown shrimp market, price trends and possible alternative sales markets. The results of these subcontracts are continuously incorporated into our work above in order to create an overall picture of a possible regional shrimp value chain.

Data and Methods

To answer our questions, we use both quantitative and qualitative approaches, including guided interviews and focus groups with stakeholders along the value chain, market inventories, representative online surveys of consumers and data from the catch statistics of the Federal Office for Agriculture and Food (BLE), the test farm network of the Federal Ministry of Food and Agriculture (BMEL) and consumer data on shrimp consumption from the "Gesellschaft für Konsumentenforschung (GfK)".

We analyse and interpret qualitative data from interviews with fishermen, fisheries officials, processors, wholesalers and retailers, restaurateurs and consumers using social-scientific methods, while statistical methods are used for quantitative market and consumer data. For example, the catch efficiency analysis of the shrimp fishery (see below) is carried out by analysing time series of the variables of individual farms using an economic regression model, or we apply the "typical farm approach" from the agri benchmark network to analyse the profitability of fishing operations.

Our Research Questions

The overarching question is: "How could regional shrimp de-shelling be competitive with the existing manual de-shelling process in Morocco?" To answer this question, we are working on a number of other detailed questions in our work packages, including:

- What exactly does the current value chain look like?

- How operational is the new technology?

- What output does the machine provide and at what cost?

- To what extent is the novel technology scalable?

- How can a machine be utilised operationally?

- Under what circumstances is it economical?

- What factors influence the efficiency of brown shrimp fishing?

- Can consumer acceptance of regionally de-shelled brown shrimps be increased?

Do regionally de-shelled shrimps have a higher quality?

- What alternative marketing channels are possible?

- How do alternative marketing channels affect the profitability of the brown shrimp fishery?

- What effects can the machine have on the value chain?

What can happen to the remains?

Preliminary Results

The results will be published or linked here on the Thünen Institute's homepage by the end of the project at the latest. However, preliminary interim results may be available at an earlier date. A final categorisation and interpretation will only take place after all the work has been completed and will be published here in the final report.

After publication, the results of the project are available free of charge to all companies active in the relevant economic sector or sub-sector.

Value chain analysis

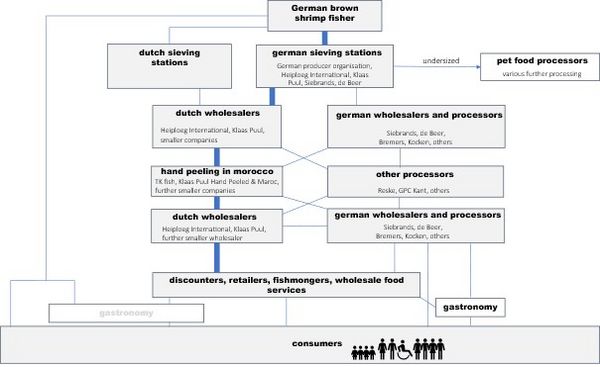

Our description of the current North Sea shrimp value chain, based on interviews with various stakeholders, confirms that it is very unbalanced and internationally organised. Most of the brown shrimps caught in Germany are bought by just two Dutch wholesalers and then sold on to retailers after the manual de-shelling in Morocco organised by them. These wholesalers achieve the highest profit margins compared to the fishing industry and retailers.

Building and testing the machine

The principle of contactless de-shelling of North Sea shrimps has been successfully tested and is now being scaled up. Tests on the resistance of the shrimp carapace, the pressure ratios that can be generated and the arrangement of the machine components have been completed. The test unit is currently being modified on the basis of these technical reults in order to test it further and collect data on energy and water consumption, labour input and potential output, for example. In addition to the shrimp meat, the by-products are the process water and the remains it contains, such as eggs, tiny pieces of meat or carapace, fats and dissolved proteins and the carapace residues themselves.

Utilisation of shell remains

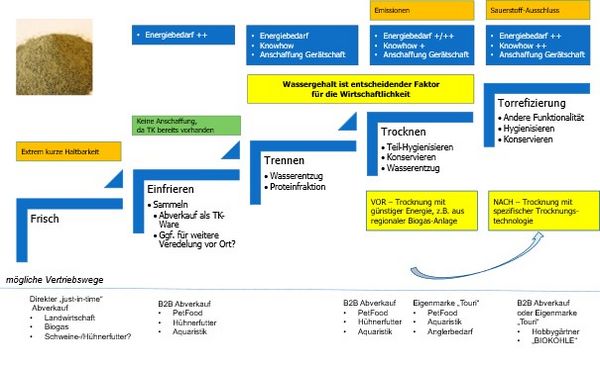

Due to the presumably available quantities, the necessary processing steps and market potential, regional utilisation of the de-shelling remains in the form of niche products appears to be the most promising. Feed additives for pets and in hobby aquaria or as a soil conditioner in hobby gardening are far progressed marketing ideas. Depending on how the shell remains are processed, considerable added value can be created here; however, this also requires high one-off and ongoing investments in deep-freeze storage and various drying processes or other processing steps, including equipment. Utilisation as chitin or chitosan does not appear to be economically feasible regionally, as EU-based production using "green extraction" processes is too expensive and immature. There is also no separate niche market for products (cosmetics, biomedical products, etc.) made from environmentally friendly or "regional" chitin or chitosan.

Efficiency analysis of the German brown shrimp fishery

So far, we have analysed the annual catch efficiency of shrimp fishermen over the past 20 years. This indicates how many shrimps a company catches in relation to the maximum quantity possible (given the production factors used, such as fishing time, cutter size and cutter age). Our results show large differences in catch efficiency between shrimp cutters and over the years. On average, catch efficiency was 77%, ranging from 50% in 2016 to 89% in 2011. We were able to identify factors from the data available to us that could explain these differences.

Characteristics in the organisational structures, such as membership in a producer organisation or ownership of the vessels by the captains, are associated with increased fishing efficiency. Other factors, such as the number of storm days per year, are associated with reduced fishing efficiency. In addition, our results show that over the entire fishing year, winter fishing, defined here as fishing activities in January and/or February, had no influence on the productivity of the vessels, but fishing efficiency decreased.

It was also shown that the ageing of the fleet reduces the vessels' fishing opportunities. Every year that a cutter gets older, the amount of brown shrimps that could potentially be caught with it decreases slightly. Ageing here represents many other factors that are closely related to the age of the vessel. In addition, the general trend of declining catches was also found.

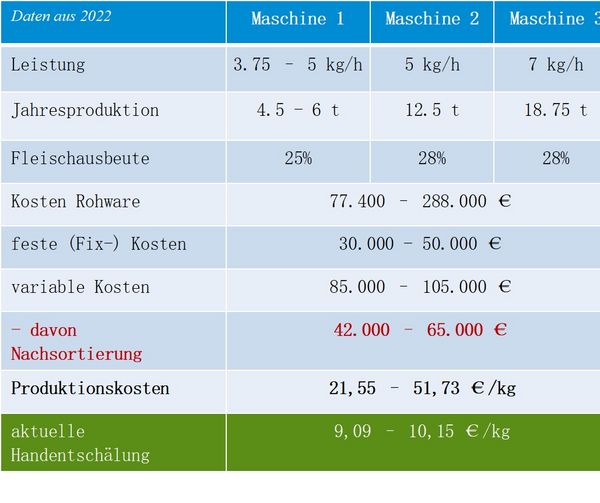

Economic calculations

There are already de-shelling machines that remove the shrimp meat from their shells using knives, rollers, rollers or similar. These de-shelling principles are based on a mechanical process in which a machine component comes into contact with the shrimp. A direct comparison of these techniques has shown that they are up to five times more expensive than manual peeling in non-European countries. The main cost drivers are the often very time-consuming re-sorting and maintenance of these machines. In addition, the yield is lower than with manual peeling. We hope to be able to improve both with the contactless principle.

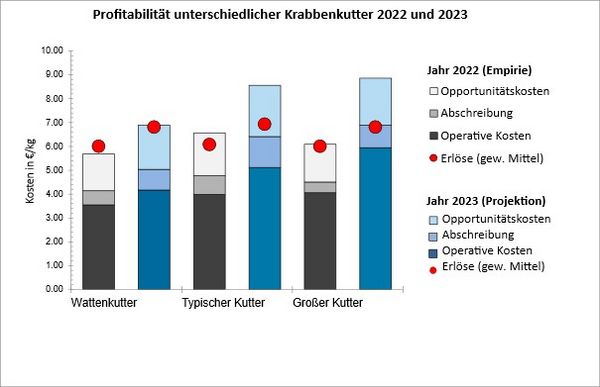

Data on the costs (operating costs, depreciation, opportunity costs), catch volumes and revenues of cutters of different sizes (30, 34 and 90 GT), which also differ in terms of crew size, time at sea, seasonal fishing times and fishing areas, were collected for 2022 and adjusted and projected for 2023.

The results show that the modelled shrimp fishing companies can also be profitable in the long term, at least in individual years. However, this is dependent on many factors that cannot be influenced by the fishermen or can only be influenced to a small extent and often fluctuate annually. These are primarily the volume of the shrimp stock, the storm days in the fishing season and the price of brown shrimps and fuel. In 2022, the small Wadden cutter shown, which fishes more in the shallower waters of the Wadden areas and is idle in the winter months (Jan - Feb/March), was more profitable than the two larger vessels, thus disproving the widespread assumption that larger vessels can be more cost-efficient per se. However, a reliable assessment of long-term profitability is only possible in retrospect, which makes investment planning and risk analyses more difficult.

Our interviews with stakeholders along the value chain show that the fishery will not be able to carry out regional de-shelling itself. Setting up their own logistics and marketing structures is too costly and there is a lack of capacity, knowledge, networks, labour and the necessary start-up capital in the fishery. In addition, fishermen consider the financial risks to be too high. Producer associations could possibly coordinate and carry out the regional de-shelling and market the shrimp meat, or third parties could set up a collective service de-shelling centre that could be used by the fishery.

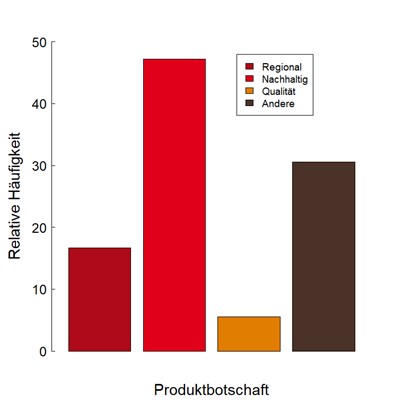

Market analysis

Sustainability, local value creation and regional origin are of particular importance to the stakeholders surveyed along the entire value chain. This can be seen in the market inventory conducted in 2022, for example: North Sea shrimps caught in Morocco are often labelled as "regional" or "sustainable" by food retailers because they are caught in the North Sea or because the shrimp fishery is certified by the Marine Stewardship Council (MSC). According to the analysis of GfK data, 64.5% of buyers of brown shrimps also consider "regionality and CO2 reduction" to be important; these can be seen as a potential target group for regionally de-shelled shrimps.

Consumers would be prepared to pay up to €0.47 more per 100 g of shrimp if they were de-shelled in Germany according to the packaging information. However, they are also very reluctant to buy shrimps labelled as "mechanically de-shelled". However, consumers often do not know much about the current processing of North Sea shrimps. For example, 33% of respondents mistakenly believe that the majority of brown shrimps are already mechanically de-shelled today. However, consumers initially rate the labelling "Shrimps de-shelled in Germany" positively. Therefore, the combination of this discrepancy should be explained in communication. Detailed information and training measures on the advantages of mechanical de-shelling could lead to a positive perception of the labelling and technology. Innovations are seen as important, but also need to be categorised and explained with appropriate communication and training.

„[…]. The North Sea shrimp still stands for the coast, probably more than any other fish“ (Gastronome from the North Sea coast)

„[…]. The customer doesn't even know what happens to the brown shrimp. They think that when they buy shrimp meat from us on the coast, it's straight from the cutter, so to speak, and then peeled somewhere. So most people don't even know that it goes to Poland or Morocco. And they also don't know how much preservative is in it. And they don't even know what a real shrimp tastes like. Because when I eat this shrimp that comes from Morocco, I have no shrimp flavour. I don't taste any more.“ (Retailer)

Links and Downloads

Our projekt featured in various media, among others in SpiegelOnline, Arte, and OZ.

Thünen-Contact

Involved Thünen-Partners

Involved external Thünen-Partners

- Georg-August-Universität Göttingen

(Göttingen, Deutschland) - US Processing Klever UG

(Großheide, Deutschland)

Funding Body

-

Bundesland Niedersachsen

(national, öffentlich)

Duration

3.2022 - 5.2025

More Information

Project status:

ongoing

![[Translate to English:] [Translate to English:]](/media/_processed_/7/1/csm_IMG_7977_large_1defaf5de1.jpg)