Equipment Chemo-catalytic Conversion

We have comprehensive equipment for the preparation of catalysts and their characterization by different techniques. Further on, we have plenty of different reactor systems which can be used for batch or continuous-flow processes.

Catalyst Preparation

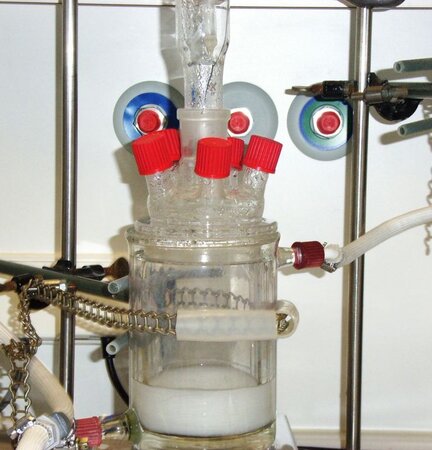

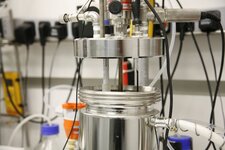

- Glass and stainless steel reactors for deposition-precipitation and wet impregnation catalysts

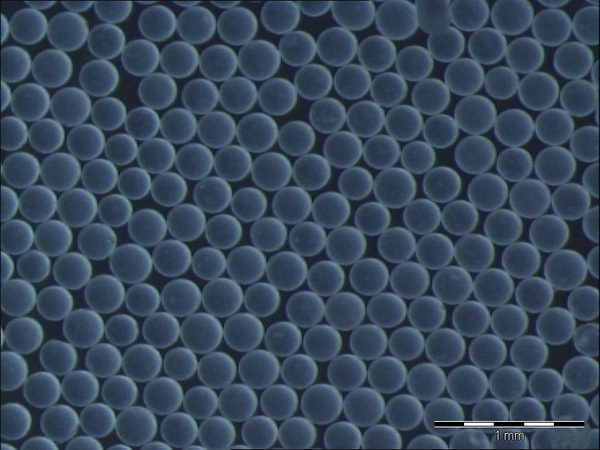

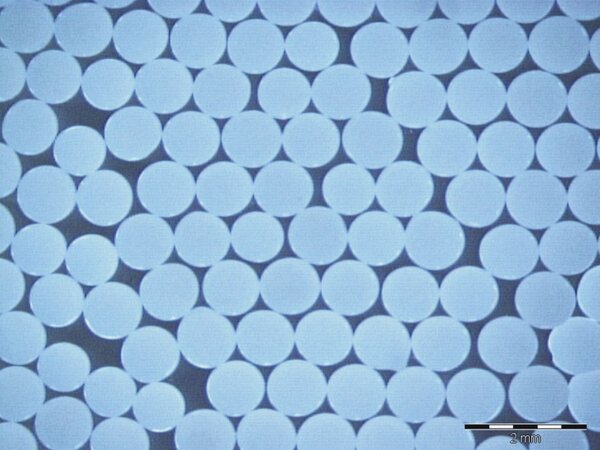

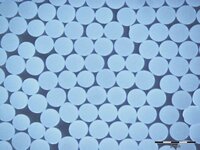

- JetCutter and dripping devices for the production of bead-shaped metal oxides by the sol-gel method

- Calcination furnaces up to 1200 °C for the treatment of support materials

- Reduction furnaces up to 1200 °C for the reduction of catalyst precursors under hydrogen atmosphere

Catalyst characterisation

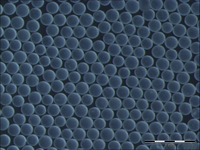

- Texture analysis by N2-adsorption (BET surface area, pore volume, pore size distribution)

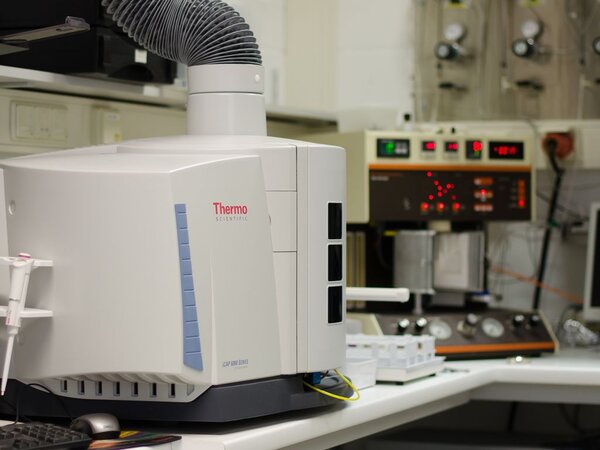

- ICP-OES for elemental analysis

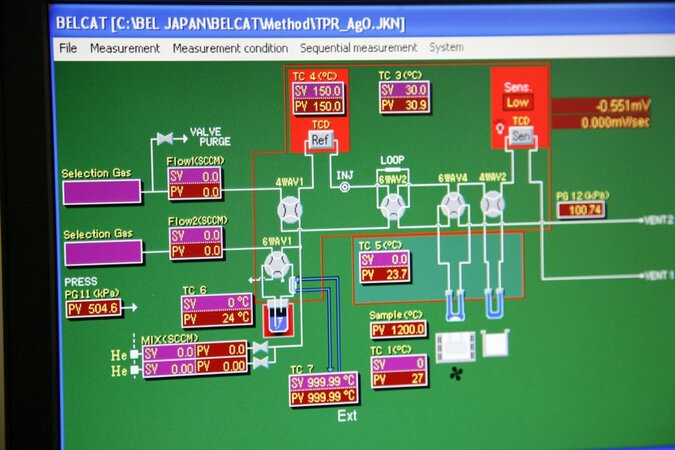

- Temperature programmed techniques (reduction, oxidation, desorption)

- CO-Chemisorption, NH3-Chemisorption, CO2-Chemisorption

- FTIR with DRIFT cell

Catalytic Reactors

- different glass stirred-tank reactors (10 – 5000 mL) for batch or continuous-flow processes

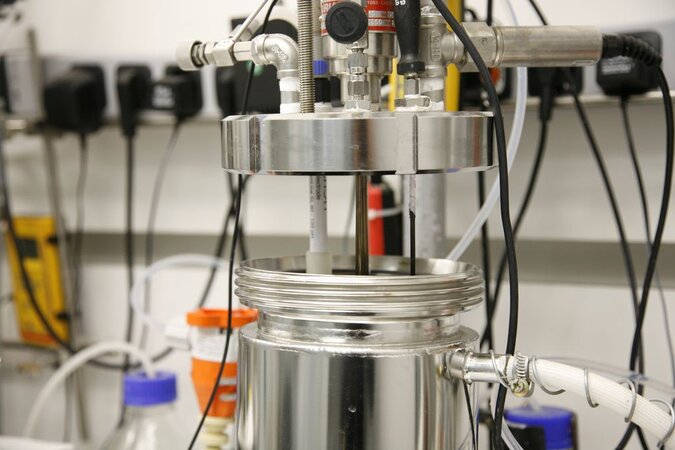

- 5 stainless steel pressure autoclaves (500 – 1500 mL) as stirred-tank reactor till 10 bar

- 2 glass stirred-tank reactors (180 and 300 mL) till 10 bar

- 5 high pressure and high temperature autoclaves made of stainless steel or hastelloy C (180, 300, 1000 mL) for temperatures till 350 °C and pressures till 150 bar

- continuous-flow trickle-bed reactor with loop (temperature till 120 °C, pressure till 30 bar)

- continuous-flow gas phase fixed-bed reactor (temperature till 750 °C, pressure till 100 bar)

Scroll to top

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)