Expertise

Biorefinery processes

Ralph Lehnen | 27.05.2022

We are working on strategies for the complete utilization of renewable resources for the production of platform chemicals and energy. In this context it is particularly significant to develop chemical and thermo-chemical pretreatment and pulping processes.

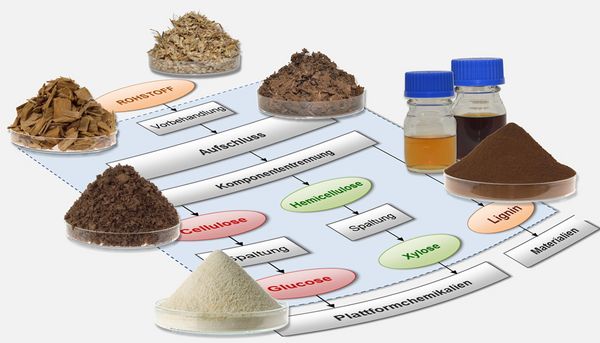

From our agricultural and forestry based raw materials and residues such as straw, crop residues, solid wood, short rotation wood crops, remaining forest wood and bark it is possible to produce almost all chemical products which are today based on fossil fuels. In biorefineries the synergetic processing of biomass into marketable chemicals and materials as well as energy is carried out gradually and in a highly integrated manner.

The first and fundamental step is the pretreatment of biomass (pulping, primary refining). During the chemical or thermo-chemical treatment the raw material can be separated into components like cellulose, hemicelluloses, lignin, extractives or lower molecular weight products like free sugars or pyrolysis oils. Similar to conventional refineries the intermediates can subsequently be converted to a variety of basic chemicals (e.g. alcohols, acids, phenols, aromatic compounds) which can be supplied to the industry by request.

The separation and disintegration of raw material components can be achieved by physical, chemical and biochemical technologies. However, processes like steam explosion and acid hydrolysis are sometimes not efficient enough and are not applicable for all types of feedstocks. Therefore alternative separation processes are under development like hot water hydrolysis, organic solvent pulping (alcohols, amines etc.) or biomass treatment with ionic liquids. The hydrolysis of the polymeric carbohydrates into monomers can be achieved by acid or enzymatic hydrolysis.

We constantly adapt the traditional methods to new feedstocks and develop alternative process solutions. Our aim is the high-efficient biomass conversion to maximize valorization of all biomass components. At the Thünen Institute of Wood Research biorefinery concepts for the material use of lignocelluloses are developed and investigated. The work at the Thünen Institute of Agricultural Technology is focused on pretreatment and saccharification processes of different agricultural harvest residues.

In order to get predominantly liquid bio-oils, biomass can be converted in one step by thermochemical liquefaction processes (e.g. flash pyrolysis or hydrothermal treatment). After further processing steps the oil is available for the production of bio-based basic chemicals or fuels. These investigations are carried out at the Thünen Institute of Wood Research.

The combination of chemical and thermo-chemical process routes is of particular interest because all biomass components and residues can be completely used. The research activities at the Thünen Institute contribute to preserve our resources and promote the development of sustainable economy.