Soil Protection

In the Working Area Soil Protection recommendations for action to implement „Good professional practice“ are developed for farmers derived from field and laboratory experiments. For this purpose, sensors are used to document soil conditions and to adjust vehicle parameters.

Narrow crop sequences, time periods with uncovered soil surfaces after ploughing, and high intensity tillage leave the top soil level unprotected to weather events – in the case of erosive precipitation, surface mud and soil erosion are the consequence. The level of soil coverage with organic residues (with straw and/or interim crops) is a key indicator for topsoil protection.

Our research activities on soil protection are divided into two areas: (1) the study of the soil surface to reduce sludging and water erosion and (2) consideration of the soil structure in the soil profile in order derive measures to avoid soil compaction.

- The intensity of the soil tillage plays a central role in the condition of the surface. It determines both the roughness and coverage of the surface as well as the looseneing level of the krumen and thus has influence on the main protective aspect against soil erosion and compaction

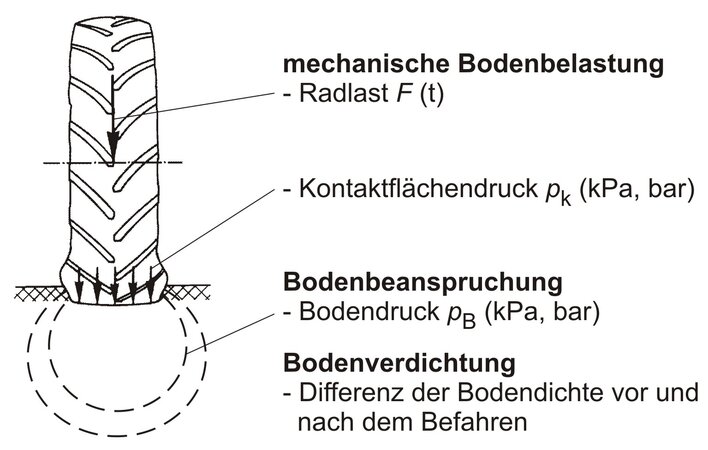

- The extent of soil compaction is determined by the level of soil looseness in soil tillage and the current soil moisture. On the part of aggregates, wheel load, tires and inner tire pressure, the contact area, the frequency of passage and portion area of the paths are important. In order to be able to adapt the use of machinery and equipment to the compaction sensitivity of sites on field / grassland and in the forest, we have developed a multi-sensor system that interrogates soil conditions and regulates vehicle parameters (such as tire pressure) fully automatically.

Expertise

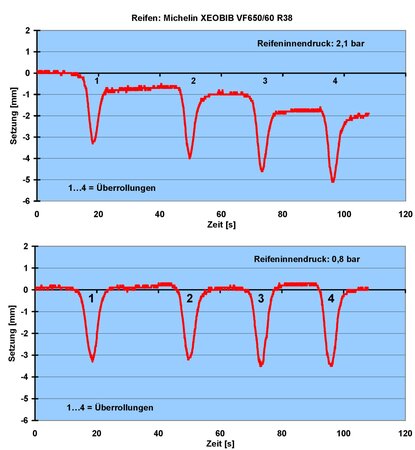

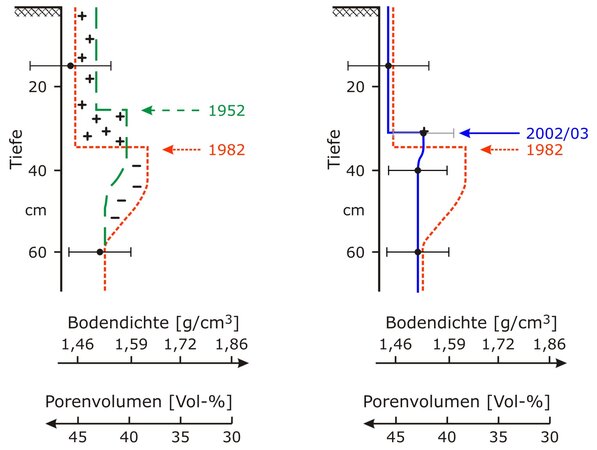

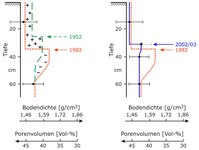

Through continuous research on soil structure over decades, we have a good regional knowledge of the actual compaction state of soils. Through the development of measuring technology in the soil (hydrostatic settlement measurement) and on the machine (ultrasonic sensor on the rim), it is possible to model dynamic processes in the machine / soil interaction. In this way questions can be answered in-situ, such as: Leaving a mechanization chain (for example, silo-forage harvester - mulcher - shredded wagon) an elastic or plastic deformation of the soil.

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_9daaef6b89.jpeg)

![[Translate to English:] [Translate to English:]](/media/_processed_/3/6/csm_Hintergrund-Ausschnitt1_0bd7111163.jpeg)